| En poursuivant votre navigation sur ce site, vous acceptez l'utilisation de cookies pour vous proposer des services et offres adaptés à vos centres d'intérêt. En savoir plus et gérer ces paramètres. |  |

Blog de lasermodule

aide blog-

Auxiliary Applications of 532nm Green Laser Diode Module In Laser Welding publié le 12/01/2026 à 10:28

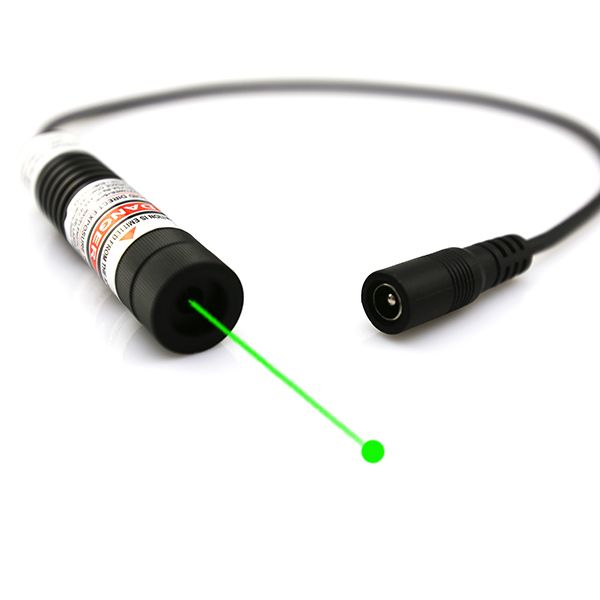

When highly precise dot measurement is processing at a longer distance or high lighting workshops, such as laser welding works, none of manual or mechanical dot aligning tool can be comparable with a 532nm green laser diode module. It applies advanced 532nm green DPSS laser tech and a qualified optic lens inside a durable anodized aluminum alloy housing tube, cooperated with constant electric power source supply. Being used as a precise positioning auxiliary unit for laser welding equipment, green dot laser alignment provides visual reference dot for the welding torch, weld seam, and workpiece splicing points before welding, providing a low-cost auxiliary solution to improve welding yield and efficiency.

After easy connects with an AC/DC adapter, 532nm green laser diode module within 5mW to 200mW begins to project highly bright and intense green light at several miles far away. Laser welding workshops are subject to interference from arc light, high-temperature reflections, and welding fumes. The 532nm green light produces clear and conspicuous green reference dot on the metal surface, allowing for rapid identification by operators or vision systems even under the influence of welding arc light. Compared to red light modules, the positioning efficiency is significantly improved. 532nm green dot laser alignment has low beam divergence ≤1.0mrad, enables precise dot positioning with a dot diameter ≤2mm within a distance of 1-3 meters. Combined with the welding equipment's control system, it can control welding positioning errors within 0.1mm, effectively reducing defects such as incomplete welds, missed welds, and weld misalignment caused by inaccurate positioning.

This glass coated lens made 532nm green laser diode module enables high transmittance green light emission in distance. After quite easy adjustable of laser beam focus and immediate concentration of green light source, it achieves increasing accuracy and brightness green dot indication onto processing surfaces. Green laser dot serves only as a visual reference and does not contact the workpiece or welding torch. It will not damage the workpiece surface or interfere with the propagation of the welding arc or laser beam, making it particularly suitable for auxiliary positioning in welding precision parts and thin-walled components. This green dot laser alignment is always installed on welding machines, robotic arms, and workbenches, providing low cost dot aligning source for welding stations in small to medium batch production.

Applications in laser welding:

Weld Seam Pre-positioning: Green alignment laser dots are projected onto the surface of the metal base material to be welded, marking the start and end points of the weld seam and key butt joint points, ensuring that the welding torch movement trajectory completely coincides with the weld seam.

Workpiece Splicing Alignment: For thin plate splicing, pipe butt jointing, and welding of irregularly shaped parts, green laser diode modules assist manual or robotic arms in completing the precise splicing of workpieces, ensuring uniform weld seam gaps and avoiding misalignment and offset.

Automated Welding Calibration: Working in conjunction with robotic welding systems, it serves as an auxiliary reference for the vision positioning system, calibrating the relative position of the welding torch and the workpiece, improving repeatability and adapting to the welding needs of small batches and diverse product types.

Spot Welding Positioning Marking: Green dot laser is marking the precise location of weld points at resistance spot welding and laser spot welding stations ensures consistent positioning during multi-point welding, especially suitable for welding precision components.

(0) commentaires

ARCHIVES

"Jean-Michel Berille, le responsable des télé-conseillers." |

- Méthode Savoir Maigrir |

|

ACCUEIL

COACHING

|

PREMIUM

FORUM PREMIUM

|

COMMUNAUTÉ

FORUM

|

RUBRIQUES

DOSSIERS

|

GUIDES

PLUS

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

Tags : ventre plat | maigrir des fesses | abdominaux | régime américain | régime mayo | régime protéiné | maigrir du ventre | |

|

|

|

Découvrez aussi : exercices abdominaux | recette wok | |

|

|

|

|

|

ANXA Partenaires : Recette de cuisine | Recette cuisine | |

|